A life full of variety at sea and ashore

Ivo Ramakers, Chief Projects & Information Officer, reflects on a life filled with diversity at sea and ashore during his 25 years in the maritime industry. His adventure began at the maritime school, where he discovered his passion for the sea. After completing his education, Ivo had the opportunity to work aboard various vessels, ranging from dry cargo to Ro-Ro and merchant vessels. His initial steps in the maritime world were taken at Sandfirden, the predecessor of MF Shipping Group.

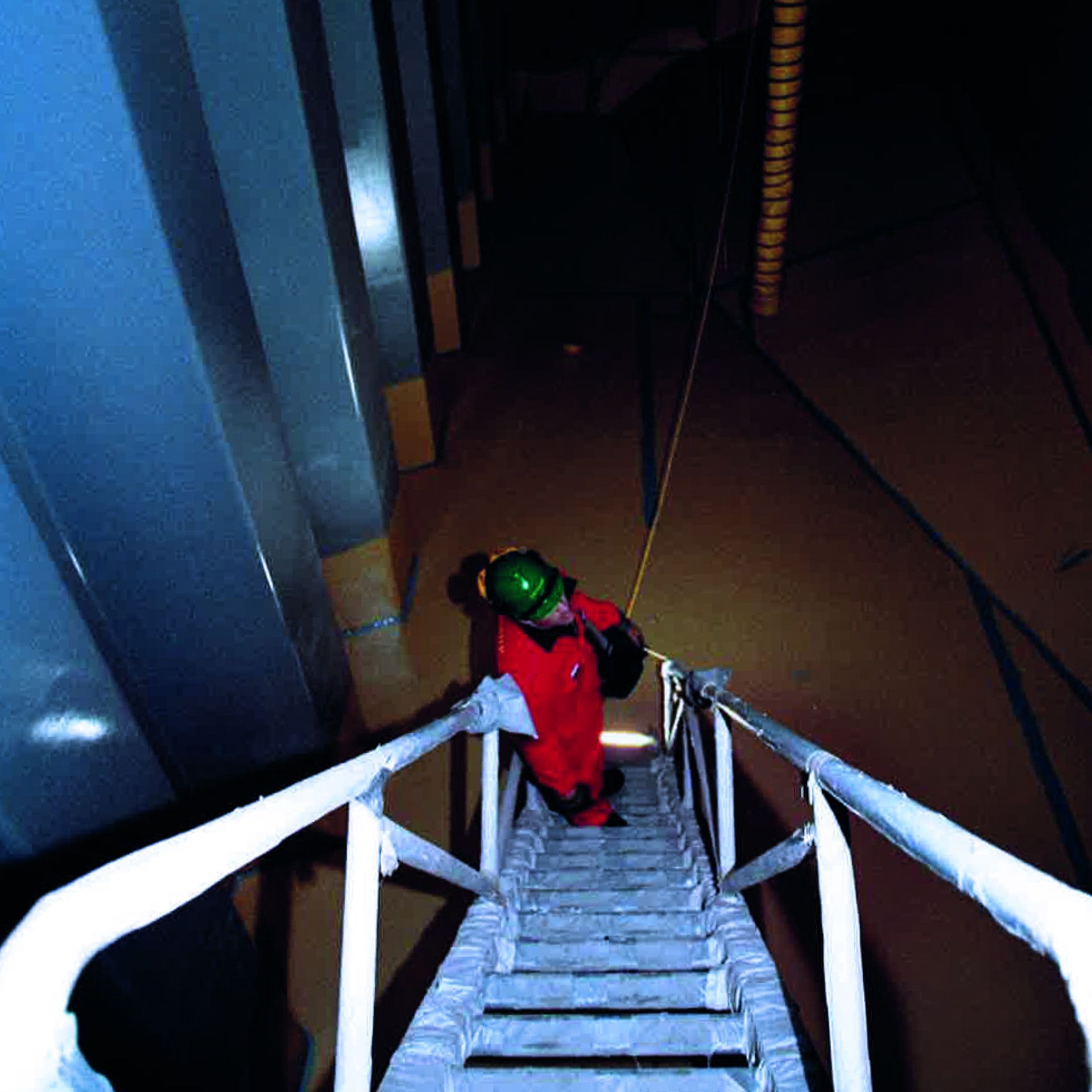

Ivo sailed on various ships in Northwestern Europe, rising to the position of Third Engineer, acquiring the necessary certifications along the way. His sea adventures were diverse; he served as Second Engineer on a voyage to the South Pole and spent time on the Baltic Sun in North America, Canada, the Caribbean, and Northwestern Europe. However, as life often unfolds, his course changed. Ivo left the ship and transitioned to an office role, where he leveraged his maritime knowledge and experience for a new phase in his career.

From sea to office

After a brief period where he served as a Chief Engineer sailing to Africa and the Caribbean, Ivo was approached by MF Shipping Group in 1996 to oversee the final construction phase of the Ice Star at the Ferus Smit shipyard. “After the vessel’s completion, I was given the opportunity to sail on it.” Given his familiarity with the Ice Star, he was appointed Chief Engineer on the Snow Star, followed by a couple of years sailing on the Nordanhav, a self-unloading vessel.

“When Thun decided to build two new tankers and preferably didn’t want to send a Swedish Superintendent to the Netherlands, it was a logical choice to ask me to oversee the construction. My sea experience, technical knowledge of shipbuilding, and understanding of onboard systems were invaluable. I knew the type of ship inside out, from construction to practical operation. The construction of the first two tankers went smoothly and efficiently, resulting in a growing demand for such vessels. At the same time, Thun decided to expand its dry cargo fleet, leading to orders for new vessels and my transition to an office role. This change came at the right time, as I was also buying and renovating a house, and starting a family during that period.”

Ivo’s extensive knowledge of vessels and his ability to bridge the gap between seafarers operational needs and shipyard construction processes were invaluable. “With my experience, I could provide valuable input to Ferus Smit shipyard where the construction took place. I understood the needs of seafarers and could brainstorm ways for the shipyard to work more efficiently, contributing to daily practices on board. I acted as the link between the demands and desires of the shipping company, their customers, the shipyard, and MF Shipping Group’s ship management requirements. I ensured that the entire process ran smoothly, within agreed-upon timelines, and in compliance with regulations. Additionally, I actively contributed ideas on how to improve the ships’ performance, such as simplifying piping systems, building ships in series for greater efficiency, and optimizing the construction process.”

Another client of MF Shipping Group, Bror Hussel, also began ship construction at a shipyard in Kampen, with technical management being awarded to MF Shipping Group. This created a demand for Superintendents, which led to Ivo’s role as Superintendent, given his experience. “In this role, I constantly monitored external developments in the maritime industry, stayed abreast of applicable laws and regulations, and had contacts with various industry associations, such as shipowners’ associations. Moreover, I actively participated in committees and had contacts with classification societies, as well as involvement with international organizations like ECSA. Thanks to these networks, I could enrich my insights and better anticipate the direction of future developments and regulations, which is crucial given the long lifespan of vessels”

“I am proud of my role in the growth of MF Shipping Group. Throughout my career, I constantly faced new challenges and opportunities, and I grew along with the company’s evolution. I have held various roles over the years, from Superintendent to Head of Technical Services, Fleet Director, DPA, and even Head of Quality. Each step allowed me to learn. My positions were never dull, partly due to the diversity of our fleet.”

Collaboration in innovation

When it comes to shipbuilding, the wishes of customer and owners, and even those of our customers’ customers, take center stage. Designing ships that provide relief to seafarers and are flexible for owners is a challenge. Maintaining a good relationship with the customers of our customers is crucial. “The pre-construction phase is therefore crucial. We strive to align everyone’s goals during this phase to avoid surprises later in the process. Fortunately, we often share the same vision and a keen eye for people’s needs. We aim to stay ahead in the ever-changing world, especially regarding regulations, environmental requirements, and new technologies. It’s a complex interplay between the owner, the customer, and MF Shipping Group to ensure the safety and well-being of the crew while also representing the interests of various parties as effectively as possible. Ultimately, to maintain a strong market position, competitiveness is key. At MF Shipping Group, we prioritize long-term relationships with our customers and maintain open communication with short lines of communication. The collaboration doesn’t end with me and the ship’s delivery; it’s an ongoing process. My colleagues within MF Shipping Group also maintain close contact with customers.”

Collaboration with Ferus Smit has led to fruitful ideas and innovations, including improvements in hull design and optimizing the power required for cargo transportation. “Our experience at sea, material knowledge, and understanding of various regulations contribute to the success of the different vessels they build,” says Ivo.

Looking ahead

With a total of 10 vessels planned at Ferus Smit for Thun between now and 2027, there is plenty of work ahead. The newbuilding program includes the replacement of 2 tankers for Nynas, 4 dry cargo ships, and 4 tankers to replace the G-class ships (the new R-class). Which will be managed by Erik Thun AB or MF Shipping Group. But that’s not all. Ivo has also been involved in parts of newbuilding projects for the Krohn-family and other clients. Considering the substantial workload, we are delighted to announce hat Superintendent Jaap Dijkhuis will be joining the Projects department as the Projects & New Building Superintendent, starting from 1 October 2023.

“We take into account the diversity of future cleaner fuels and use ‘futureproof’ engines capable of running on multiple fuel types, making it easy to transition to fuels like methanol. We are exploring for example hybrid propulsion, allowing us to add extra power when needed. Our goal is to generate power on board more efficiently. An example of this is switching from hydraulic cargo pumps to electric pumps, which yield efficiency benefits. We are also studying how to use battery technology and the ship’s network more efficiently to reduce fuel consumption. Batteries can potentially replace the third auxiliary engine, allowing us to make optimal use of the generated energy.

For many years, we have strived for maximum efficiency, aiming to transport as much cargo as possible within the constraints of ship measurements and applied engine power.

Modifications to existing vessels

“In my role, I have also had the pleasure of being involved in the purchase or sale of ships and guiding modifications to existing vessels, such as at JT Cement AS, where we purchasedand converted several dry cargo ships into cement carriers. For the Projects Department, this meant a lot of calculations, including those related to electrical power on board and the optimal placement and type of unloading equipment. We also looked at cargo handling and equipment. Our role was to brainstorm how these modifications seamlessly integrate with the rest of the vessel.

In addition to our collaboration with Ferus Smit, we have also had positive experiences with other shipyards such as Royal Bodewes. We consider Ferus Smit our “homeyard” due to their efficiency and excellent engine room designs. We strive to reuse those successful designs on other vessels, resulting in significant cost and time savings. This also benefits our Technical Department. Furthermore, we benefit from procurement advantages by using series of engines and auxiliary engines on different types of ships, rapidly improving our levels of knowledge. Through our decades-long collaboration with Ferus Smit, we have built a strong relationship and a deep mutual understanding.”

At one point, Thun urgently needed larger tonnage. Within two years, five ships were required. The lead time at Ferus Smit was longer at that time, partly due to a lack of newbuilding slots and manpower, which led Ivo to China. “Designing the vessels was very challenging due to language barriers and convincing Chinese shipyards of our designs and philosophy. This required weeks of intensive communication after carefully auditing which shipyards met our requirements. Sometimes, I hear doubts about the quality of ships not built in the Netherlands, which I find unjustified. The basic design, along with the quality of the shipyard, determines the quality of the vessel, and we have had good experiences with the Chinese shipyard.”

As for his own future, Ivo sees plenty of challenges ahead. “The dynamics in the shipping industry remain significantly high. There is still much to do and learn, and, above all, I still enjoy my work at MF Shipping Group. My career has been a versatile journey so far. Shipping continues to be my passion, and I am ready for whatever the future holds.”